Aspects of wear comfort

In the field of textiles and clothing industrial, wear comfort is no doubt one of the most important aspects. You can not run wearing a airtight clothes, which will make your body sticky and wet, human beings even couldn’t function well if they are not comfortable, and sometimes can cause very bad results in some scenery like driving a car, handling work which need concentration, comfort becomes a factor that really matters safety.

However, comfort has many different aspects, as summarized by one writer: ‘Comfort is a complex matter, with physical, physiological, and psychological factors interrelated in an unpredictable combination which constantly undergoes variation’.

But what a good cloth actually do to make you feel comfortable? The answer is by modifying the heat loss from the skin surface and at the same time has the secondary effect of altering the moisture loss from the skin. Perspiration is an important mechanism which the body uses to lose heat when its temperature starts to rise. Heat is taken from the body in order to supply the latent heat needed to evaporate the moisture from the skin.

There are two forms of perspiration:

- Insensible: in this form the perspiration is transported as a vapour and it passes through the air gaps between yarns in a fabric.

- Liquid: this form occurs at higher sweating rates and it wets the clothing which is in contact with the skin.

When perspiration takes place to cool the body, the water exuded through the skin appears initially as liquid which evaporates at once (in comfortable situation) and forms moisture vapour. This vapour is removed from the vicinity of the body, either by convection or through the clothing worn on the person, carrying heat away with it.

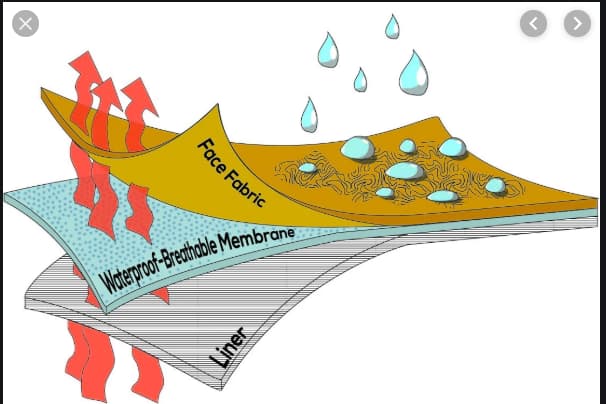

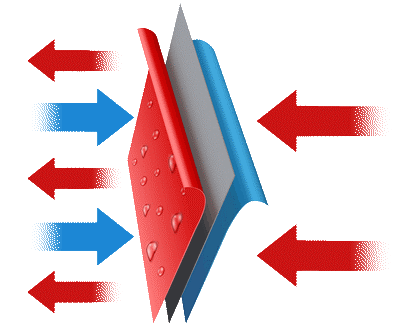

When the moisture vapour reaches the inner surface of the fabric, several events can take place. The vapour may pass through the fabric system to its outermost surface, there to be carried away by the air. At the other extreme, it may be prevented from escaping through the fabric system if a component of the latter is impermeable, and will condense at some position in the system.

The transfer of additional moisture vapour through the system will then be impeded by the liquid water layer so formed, and the plane of condensation will gradually move inwards form the impermeable barrier until eventually condensation takes place at the inner layer of the system, at the surface of the body, as soon as moisture is exuded through the skin, marking the onset of sensible perspiration.

There are two forms in which this discomfort is manifested. In hot weather, perspiration is the only problem, and the sensation of wetness, though a nuisance, does not lead to danger unless the temperature is so great that heat stroke or dehydration is possible.

In cold weather, though, a more urgent risk arises. If, for instance, heavy work has been in progress and then is discontinued, the production of heat (and moisture) will continue for some time after work has ceased. If this moisture is not evaporated (by the heat generated in working, for instance), condensation will occur and the wetness will be evident, as before.

Another hazard now comes into operation. The liquid moisture which forms inside the fabric acts as a much better conductor of heat than the air which it has displaced, so that the heat loss from the body increases by a very large factor. The resulting initial cooling effect of this liquid water by conduction is then increased by the enhanced loss of heat from the body surface in an effort to supply latent heat of vaporization to transform the liquid water into vapour. Because of this demand, heat losses from the body become immense and a grave risk of frostbite or hypothermia develops, possibly leading to irreparable damage or even death.

Various test methods are available for assessment of the fabric permeability. The most conventional method is to calculate the permeability by Equation:

P = D.S

where P is permeability coefficient, D is diffusion coefficient and S is solubility coefficient. This equation has been widely used in the literature. However, the problem of penetrant diffusion in and permeation through inhomogeneous fabrics is more complex. This equation is only available in ideal permeation conditions such as at the limit of low permeability and diffusion concentration.

At the same time, a number of standard methods have been developed by several national and international organizations such as the American Society for Testing and Materials(ASTM), the American Association of Textile Chemists and Colorists(AATCC), the British Standard (BS), the Japanese Industry Standard (JIS), the International Standards Organization (ISO), and others to assess the permeability of fabric to air, water, chemical, etc. These test methods are able to meet the requirements for quality control as well as research work to a certain extent.

In general, fabric permeability tests include air permeability, water permeability and chemical (gaseous, liquid or solid chemical) permeability, which is related to the penetration of a gas, liquid or solid material to pass through such fabric barrier and then desorb into a specified medium. Each type of fabric permeability has different testing methods.

Air permeability

Air permeability is defined as velocity of an air flow passing perpendicularly through a test specimen under specified conditions of test area, pressure drop and time (BS 3424-16-1995). The principle of the test is that the rate of flow of air passing perpendicularly through a given area of fabric is measured at a given pressure difference across the fabric test area over a given time period. In the field of textiles and clothing, air permeability is often used in evaluating and comparing the ‘breathability’ of various fabrics (coated and uncoated) for such end uses as raincoats, tents, and uniform shirtings. It helps evaluate the performance of parachutes, sail cloth, industrial filter fabrics, and the covering fabrics of pillows and duvet covers.

Thermal and water-vapour resistance

To ensure the clothing comfort to wear in, there is another vital important test need to be done, i.e. thermal and water-vapour resistance testing. In standards, it is called measurement of thermal and water-vapour resistance under steady-state conditions, which is usually done via a instrument called sweating guarded-hotplate tester. Learn more this instrument and the test from here.